50mm -500mm (2,, -20 ")

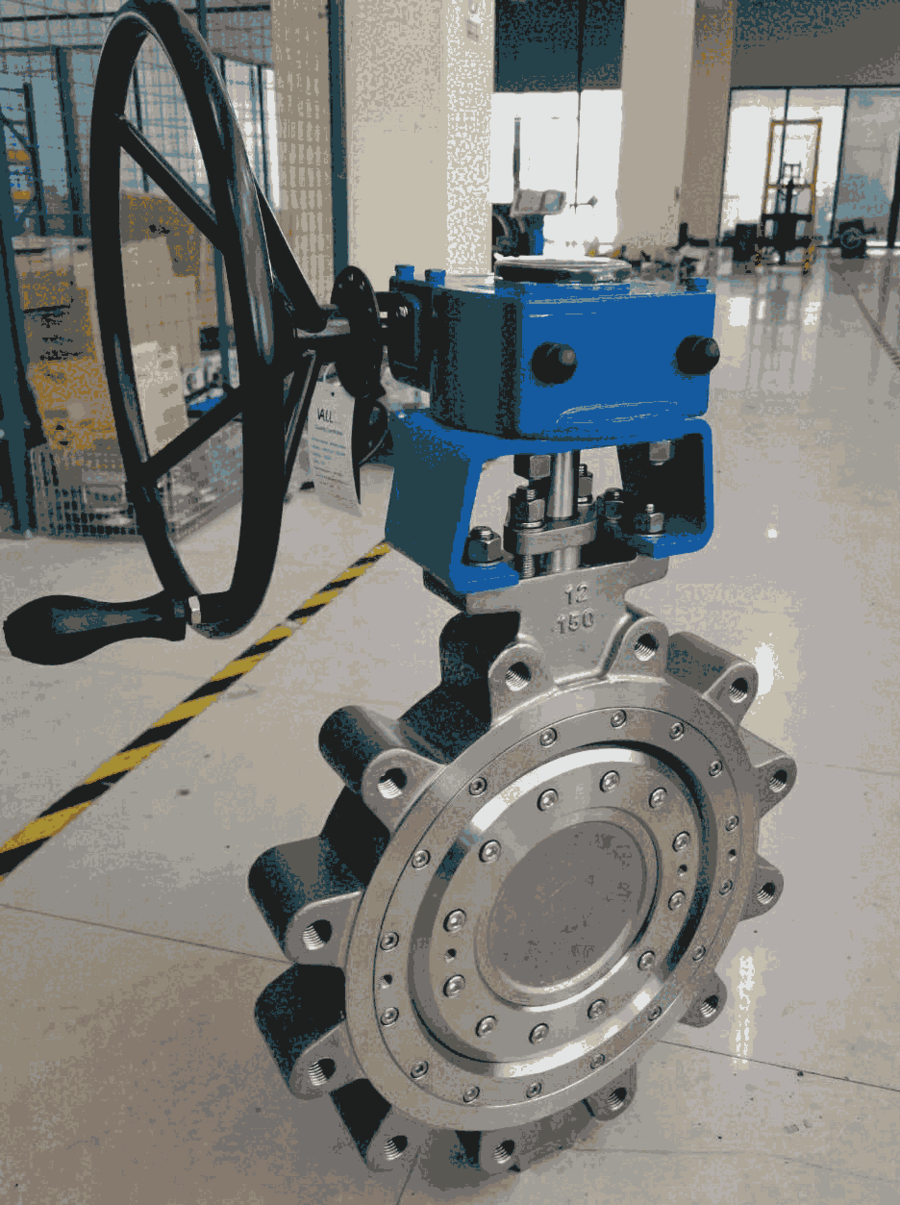

Borray Valve and Control Systems is proud to provide high-performance, high-quality butterfly valve products to meet the requirements of today's market. The rated pressure of the 30H wafer type and 31H trunnion type butterfly valves in the series is 16 bar.

function

The wafer type butterfly valve with flange positioning holes is suitable for connecting ANSI 125/150, BS 10 Table D and Table E

BS 4504 NP 10/16、DIN ND 10/16. AS 2129, JIS 10K and other flange standards.

The unique design of the dual D connection between the valve stem and valve plate can completely avoid the drawbacks caused by traditional butterfly nails and pin connections. For example, the gap between the screw and pin connection is the main cause of valve leakage, as well as common problems such as corrosion and disassembly difficulties caused by vibration.

The casting edge of the valve plate is mechanically processed and manually polished, so it can improve bubble sealing, reduce the torque generated when the valve is opened and closed, and extend the service life of the valve seat.

The unique design of SPIROLOX retaining ring and valve stem retaining C-ring specifically prevents accidental detachment of the valve stem.

The unique "tongue groove embedded" valve seat design can reduce the torque generated between the valve plate opening, closing, and the valve seat, and improve the retention force between the valve seat and the valve body. The valve seat is specially designed for the installation of sleeve and welded flanges, and the valve seat completely separates the valve body from the fluid medium.

When installing the valve, there is no need to consider adding any gaskets or gaskets between the valve and the flange.

? interference fit shall be adopted for the fitting of valve seat, central hole diameter of valve plate, valve stem and valve seat hole, and acetaldehyde shaft sleeve, a corrosion resistant and wear-resistant material, shall be used to bear the transmission force of the actuator.

The design of the bidirectional U-shaped seal can be adjusted independently and can serve as a bidirectional seal.

The connection of the actuator fully complies with the international ISO 5211 standard and can be directly connected to any pneumatic, electric, and manual actuator of Boray without the need for any connecting brackets.

Nylon 11 valve plate coating

Nylon 11 is a thermoplastic, plant-based coating. Nylon 11 provides excellent corrosion resistance, which can withstand 2000 hours of salt spray testing and 10 years of seawater immersion testing without any signs of corrosion on the underlying metal. In short, the ductile iron valve plate coated with nylon is both economical and practical, and can completely replace aluminum bronze in various water media. Especially in seawater media, it has more outstanding corrosion resistance than 316 stainless steel. It has superior wear resistance, impact resistance, and UV resistance. The valve plate coated with nylon 11 can reduce the coefficient of friction, increase the service life of the valve, and reduce the torque when the valve plate is opened and closed. Nylon 11 is a coating approved by the US National Food and Drug Administration (USFDA) to prevent bacterial growth and growth.